Vertical software will make manufacturing (up)right

Design, development, production, and the planet exist together in harmony.

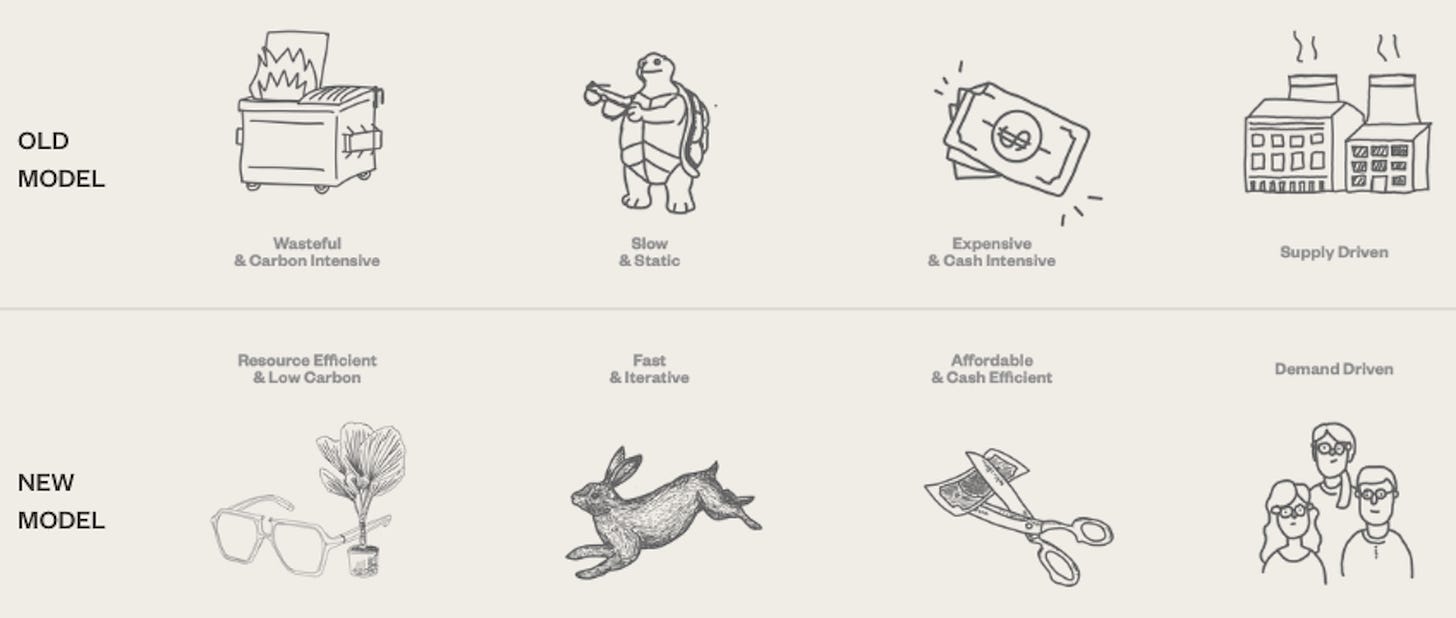

For the past 20+ years businesses have been attempting to evolve manufacturing and supply chains, but the legacy systems they’ve been using for almost a century remain the default.

Their solution?

Use the same systems, but increase efficiency by improving the connection points.

“We need more suppliers! Better demand forecasting and order management! Better analytics for operational efficiency!”

Okay, sure, but connection points are where systems break down. Global supply chains are wholly disjointed: there are hundreds of connections in each one. A single weak spot in a chain puts the whole system in danger. Trying to tighten connections and modernize between legacy systems is futile — one way or another, the chain will keep breaking. Plus, resources will continue to be sucked inefficiently, and unsustainable levels of carbon will be emitted in the process.

Say it with us: there had to be a better way.

Our solution?

We built a complete vertical software stack, covering the end-to-end process of realizing a specific product: design, development, ordering, and manufacturing. Our model leverages 3D printing technology and innovations in robotics and material science — specifically geared towards the products we produce.

All the dots in the chain are inherently integrated because we designed it that way. The multitude of connection points needed to make the old system run vanish.

In the old model, design for manufacturing (DFM) was a crucial but enormous set of connection points. It presented a huge challenge for designers, developers, and manufacturers alike. Designers and developers used one set of technology to flesh out their ideas, before bringing them to manufacturers who used a different set of technologies to try to turn those ideas into a physical reality. More often than not, the original concept unraveled and the product that got mass manufactured looked like the concept’s distant relative.

The DFM linkages alone take months, and the longer it takes to bring a product to market the more you find yourself playing catch up — trying to predict trends by looking into a crystal ball. Now you’ve got a vicious cycle, falling further behind while creating more waste and more emissions.

In the new model, brands can turn their concepts into reality automatically. When designers and developers work together within the same systems as their manufacturers, and the capabilities are flexible thanks to 3D printing technology, the need to design for manufacturing disappears.

We’re no longer trying to make different systems speak to each other. Instead, our stack integrates algorithmic design. In the design process, we automatically create the files that drive manufacturing, eliminating those connection points. This allows for seamless iteration in the prototyping stage, ensuring that no design elements are lost and speeding up the entire development period.

Our stack is, as always, resource-efficient and low carbon. As carbon credits loom on the horizon, companies that use low-carbon supply chains and produce only what they need will be set up for long-term success. A vertical software-driven supply chain also eases the burden of tracking energy use and emissions. Those that maintain the status quo may be caught in a lurch, scrambling to rethink their whole supply chain when it’s already too late.