Zero-inventory business models make $ense

Global supply chains have been getting messier and stretched thinner for decades. They weren’t built for even a fraction of the variety of product they’re pumping out today, as trend cycles get shorter and consumers expect more options.

The delicate balance broke when COVID and the Russia-Ukraine War exposed the cracks in the system, and they’ll continue to get much worse. BoF reported last month that over 75% of fashion executives see shipping costs, transport capacity, and ports disruptions as major concerns in the coming years.

It’s clear that the system is broken - let’s turn it on its head:

What if global supply chains weren’t the default? What if we made products, end-to-end, in one place, and the supply chain disappeared? What if we manufactured goods close to where they’re sold, insulating the process from the precarity of global logistics? What if we didn’t need so much carbon or so many raw materials to execute the process?

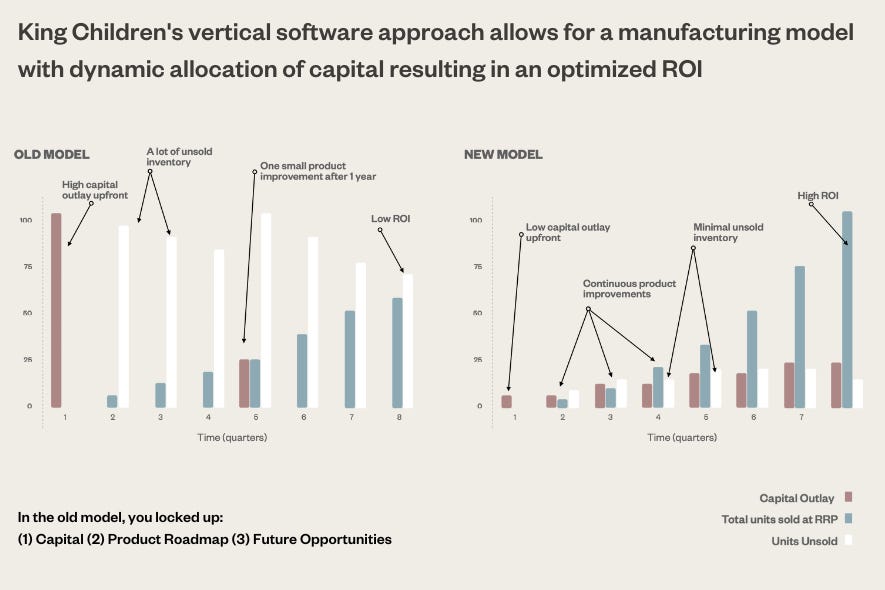

To paint a picture of the differences between the current model and the new one we’ve created, let’s break down this graph:

The old model locks up your capital…

with 3 parts to invest in:

Design - your vision!

Development - making (a producible version of) your vision a reality: finding suppliers, reviewing samples, and making decisions before moving into production.

Inventory - including transport, logistics, and warehousing. Suppliers have stuck you with high volumes, so while you’re launching your product you’re also paying to store the overstock.

Bringing your product to launch burns up to 2 years and locks up your $$$. Simultaneously, your offering is getting further from market relevance as trends and seasons change. Once you’re finally in the market you’ll learn which products are winners, while the losers collect dust in warehouses. You then need to do something with the unsold inventory, probably selling it discounted and seeing your margins dwindle.

If you manage to financially make it through the first introduction of your product and you restock the winners, it takes 9 months to hit the shelves and you’re hit with that same high minimum quantity to try to sell. You’re likely crossing your fingers it will still be relevant then. Your cash is again locked up while you wait, and you’re debating sending the remaining losers to the landfill.

It’s not a good business model, and it’s not good for the planet.

The new model is an iterative process…

where investing looks much different:

Design + development are fully integrated, bypassing design for manufacturing. No sourcing materials or coordinating with multiple suppliers to try to assemble a finished product! Complete the entire process in as little as 2 months.

Inventory is drastically lower, and it’s produced close to home. Bring a small offering to market to quickly understand what’s winning and what’s not. Restock in just 4 weeks, dynamically adjusting your inventory to work for your brand. You’ll never hold on to a bunch of product you can’t sell.

Our partners don’t invest all their capital up front or lock it in place for long periods - they bring products to market 10x faster, with 1/10th of the capital, and they have cash flows that cycle 10x faster.

Quick, small batch production allows you to gather information from the market and actually use it to change your roadmap. Decisions translate into business impact, immediately and by design.

This is ONLY possible when all three aspects are executed through a single platform. It is the business model that will transform the manufacturing industry and the trajectory of our planet.