Zero-waste manufacturing is cool

For the next few installments, we’ll be diving deep into King Children’s business model. Welcome to part one on zero-waste manufacturing.

The enormous footprint of the products we buy is a recipe for a hot planet, or more realistically, climate disaster.

This is the result of inefficient methods that gulp our finite resources. The combination of waste created and energy expended adds up:

Production through supply chains consumes 54% of global energy sources and emits a whopping one fifth of total carbon.

The fashion industry alone is responsible for almost half of that: 2.1 billion metric tons of carbon are emitted annually.

Achieving low carbon supply chains is a must in the pursuit of decelerating climate change and achieving a sustainable future. To fundamentally shift the manufacturing industry and have a huge impact on global sustainability, we must drastically scale up resource efficiency while scaling down carbon intensity.

Of course, countries and businesses around the world have made commitments to shrink their fossil fuel consumption in an effort to limit the planet to 1.5C of warming. With peak use globally still on the horizon, how does this happen in practice? The current global systems require tons of raw materials and goods to take trips around the world before they hit the shelf — inherently unsustainable! — so businesses must decipher the path forward for their supply chains.

We’ve rethought the whole system:

Zero-waste manufacturing is in

King Children’s platform creates no material waste – we built it that way!

Our vertical software system and high-tech, automated micro-factories power the future of manufacturing. We leverage our localized micro-factory network to produce close to where products are sold, and we only make the amount brands need. We eliminate the carbon emissions needed for inventory, warehousing, and transportation - in total using up to 90% less carbon in our supply chain compared to traditional global networks.

In production, we individually craft each frame out of 100% bio-based Polyamide made from sustainably-farmed castor bean oil, using proprietary laser-based technology. Through 3D printing the polyamide powder is fused together, and any leftover powder is collected and used for the next pair.

At its core, this process is resource efficient and low-carbon. It’s the engine powering sustainable business and a cooler future for our planet:

High resource efficiency enables businesses to cut costs for raw materials, and conserves our finite resources

Using minimal carbon supports climate goals and fosters simple, accurate carbon tracking

Our complete vertical technology stack is the first of its kind to support brands in achieving their Net Zero goals as Scope 3 emissions, which typically make up 80% of total emissions, disappear

Looking ahead… we’ll expand our model to other consumer goods like footwear, jewelry, furniture, and lighting.

What we’re reading

KC co-founder and CEO Sahir Zaveri’s article on 3DPrint.com on our unique post-processing technology (in advance of speaking at the Additive Manufacturing Technologies conference in New York this week!)

Extra credit: did you know?!

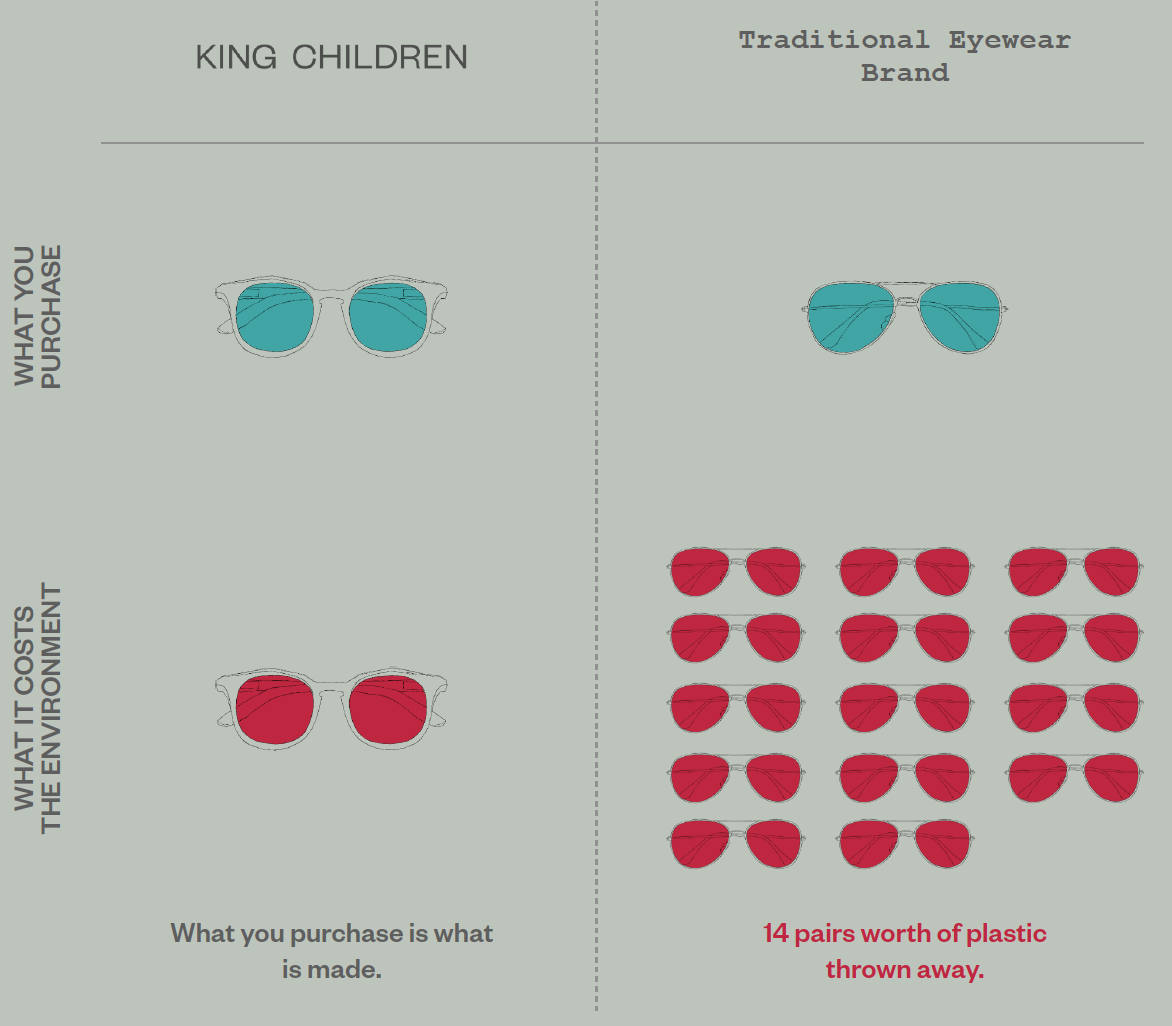

Remember in our last newsletter we mentioned that acetate eyewear (the most common eyewear material) is made by taking a block of acetate and chiseling it alllll the way down to just the frame design? And then the rest gets thrown out? And that amounts to up to 80% of total material used in the process?

In sum, for every pair of frames a consumer buys, 14 pairs worth of eyewear in plastic go directly to the landfill:

For scale: 2.5 billion units of eyewear were sold in 2021. Let’s assume at least half of those were made from acetate - that’s 17.5 billion pairs worth of eyewear waste in a single year alone. This system sucks our resources and emits tons of carbon in the process, but glasses allow us to see! They protect our eyes from the sun and other elements when we’re doing activities we love. They empower us to express ourselves through style. We need eyewear, we don’t see a future without it. We DO envision one where we can make eyewear that supports people’s needs AND businesses while protecting the planet, and we’re not letting our dreams be dreams.